45+ years of experience

With our expertise in the design and production of high quality high pressure die casting moulds, and our specialisation in high productivity injection moulds with heated runners, we are constantly pushing the boundaries of precision engineering.

We offer a wide range of high-precision services to meet your most demanding needs. From custom mold design to plastic production and precision part manufacturing, our team has unparalleled expertise and attention to detail to handle every stage of your project.

With over 45 years of experience, cutting-edge technology and a commitment to excellence, we operate in the medical equipment, automotive, home furnishings and construction project sectors, offering reliable, high-quality solutions. We are your trusted partner in providing components and services that exceed your expectations.

Quality and excellence are our core values. Our raw materials are mainly sourced from reliable suppliers in Germany and Austria, ensuring that every product meets the strictest industrial requirements. Strict quality control procedures guarantee that our moulds and components meet the highest standards, providing reliability and performance that customers can trust.

Our Services

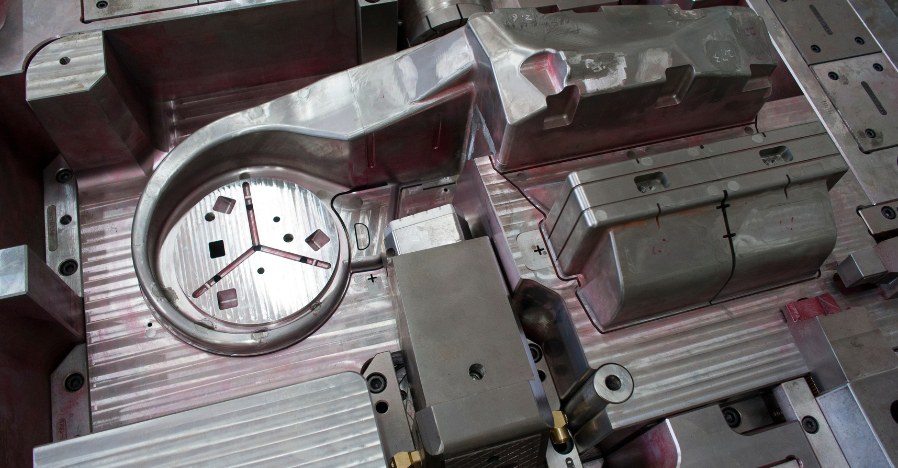

Manufacture of Injection Moulds

At Stratos Moulds And Parts, we specialise in the manufacture and repair of high precision injection moulds with heated runners, which meet the most stringent industrial requirements.

From initial design to production completion, we offer customized solutions that ensure long-term performance and durability. With production capacity for structures with maximum dimensions of 700×500 mm and weights of up to 600 kg, we ensure high quality and reliability in every product.

Services

- Moulds Study and Design: We use advanced CAD/CAM/CAE systems to design molds that meet your exact production needs, with the goal of reducing cycle time and saving resources.

- Injection Mold Manufacturing: Our moulds are made from high strength materials, offering precision and reliability in mass production.

- Testing and Quality Control: Each mold is thoroughly tested prior to delivery to ensure the ultimate in quality and performance on your production line.

Advantages:

- Innovative Design: We use advanced design software to create highly efficient and sustainable moulds.

- Durability: Our molds are made from materials that resist wear and tear and stress, ensuring a longer lifespan.

- Increased Efficiency and Production Quality: Our specialisation in high productivity injection moulds with heated runners ensures excellent results and reduces waste.

Manufacture of High Pressure Die Casting Moulds

At Stratos Moulds And Parts we offer high quality high-pressure die casting moulds, which are designed to withstand extreme conditions. These moulds are ideal for casting metals such as aluminium, magnesium and zinc, ensuring that each component is precisely formed.

Our production capacity allows for manufactures with maximum dimensions of 700×500 mm and weights of up to 600 kg. With our experience and cutting-edge technology, we guarantee high quality and reliability in every product. Trust us to meet your molding needs and provide you with solutions that stand the test of time.

Services

- Mold Design: We develop high-pressure, precision molds tailored to your needs for mass production of parts with demanding specifications.

- Mold manufacturing: We use high-strength materials that ensure the long-term use of the moulds, even under extreme temperatures and pressures.

- Production optimization: Our molds are designed to reduce production times and improve efficiency.

The high pressure die casting process requires high quality molds that compete with the rigorous demands of the industry. At Stratos Moulds And Parts, we have developed expertise in creating and repairing such moulds, providing reliable solutions to our customers.

Advantages:

- Reliability and Performance: Every mould we manufacture undergoes rigorous testing to ensure performance and reliability in production.

- Materials Specialisation: Depending on your needs, we use various alloys and materials that allow for efficient casting.

- Extensive Support: We offer full support throughout the life of the molds, including preventive maintenance.

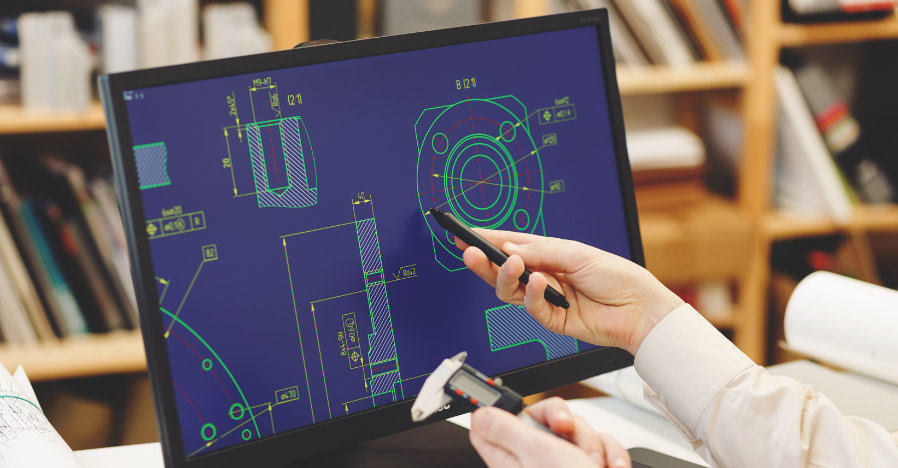

CAD/CAM/CAE Design

CAD/CAM/CAE technology is the foundation for innovation at Stratos Moulds And Parts. We utilize the best tools in the industry to create designs that optimize the manufacturing process and reduce costs. Stratos Moulds And Parts. We utilize the best tools in the industry to create designs that optimize the manufacturing process and reduce costs.

Services

- Design of products and canopies: We offer complete mold design from scratch, with absolute precision and focus on performance.

- Simulations: We incorporate simulations (CAE) to test and evaluate the performance of designs prior to production, ensuring optimal operation.

- Production optimization: With CAD/CAM tools, we improve production processes and reduce margins of error.

Using state-of-the-art CAD/CAM/CAE tools, Stratos Moulds And Parts offers complete design solutions for the manufacture of high-precision moulds and mechanical components. Our skilled staff uses the latest programs to create optimized designs, which are tested in simulation to achieve maximum product functionality and efficiency.

Advantages:

- Precise Design: Our designers work with precision and attention to detail, ensuring that each design competes with your needs.

- Performance Simulation: The use of CAE software allows us to simulate the operation of moulds before production, avoiding problems in the initial phase.

- Improved Design: We are continuously reviewing and improving our designs based on customer feedback and technological advances.

Product Development and Improvement

At Stratos Moulds And Parts, we undertake the full development of new products and the improvement of existing ones, helping companies to adapt and optimize their products for greater efficiency and competitiveness in the market.

Services

- Integrated Product Development: We provide services that cover the entire process, from design and prototype development to final production.

- Improvements and Upgrades: We offer suggestions for improving your existing products in order to improve their performance or reduce production costs.

- Ongoing Support: Our team works closely with customers to ensure that final products meet all requirements.

At Stratos Moulds And Parts we do not only provide manufacturing services, but also complete product development solutions that incorporate the latest technology. Our team works closely with clients to develop and improve their products, ensuring they are competitive in the marketplace.

Advantages:

- Prototyping: We create product prototypes for testing and feedback, ensuring that the final product meets expectations.

- Existing Products Upgrade: We analyse and improve your existing products to increase efficiency and productivity

- Extensive Market Experience: Our experience in various sectors allows us to propose solutions that meet the needs of the modern market.

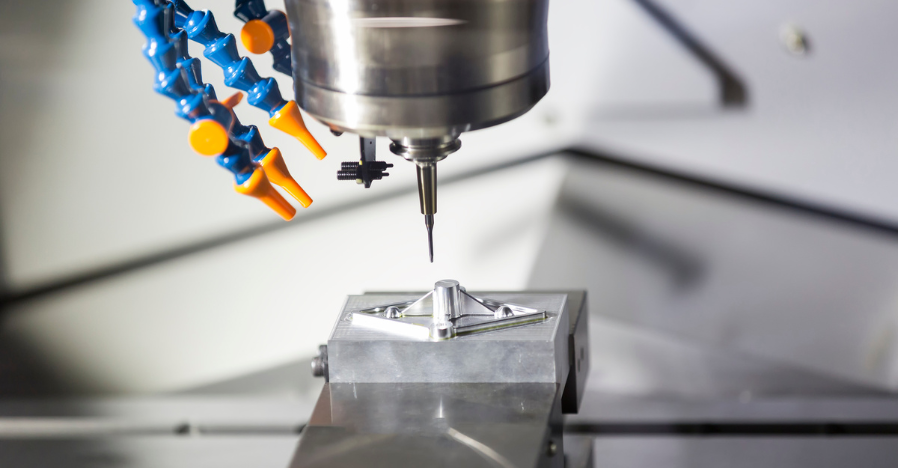

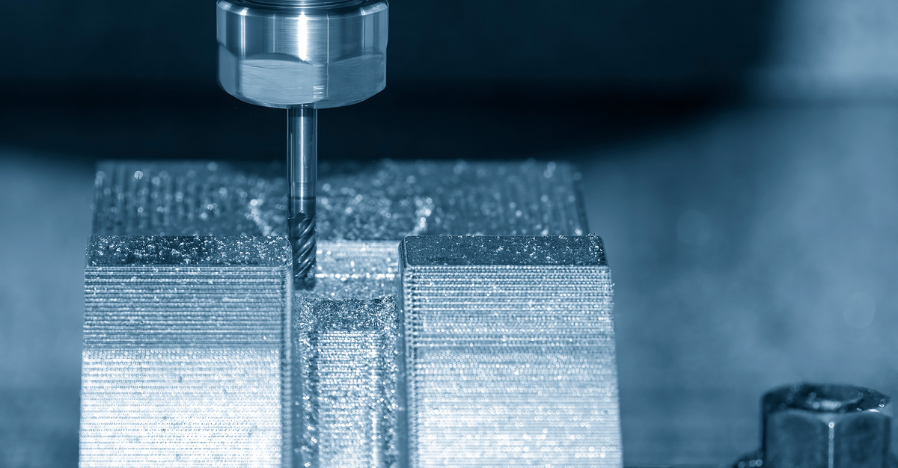

Precision CNC Component Manufacturing

At Stratos Moulds And Parts, we offer precision component manufacturing services to meet the most demanding industrial needs. Using advanced CNC technology and specialized processes, we ensure that each component is manufactured with the utmost precision and attention to detail.

The CNC machining operations of Stratos Moulds And Parts ensure the production of precision parts to the strictest specifications, using advanced technologies and control systems. Our CNC machines allow us to manufacture parts with millimetre precision, even for the most demanding applications.

Services

- Wide Range of Materials: We ensure precision and quality finishes on a variety of materials, from metals to composites.

- High Precision Tolerances: Our CNC machines provide millimetre precision, ensuring perfect fit and function of your machines.

- Quality Assurance: Each component is carefully tested to ensure it meets your stringent requirements.

- Custom Designs: We create components according to your exact specifications.

- Durability: Each component is designed to withstand harsh operating conditions. Advantages:

Advantages:

- Flexibility: Ability to manufacture a wide range of components, from prototypes to mass production.

- Rapid Delivery: We leverage an extensive network of suppliers for fast production and delivery.

- Ongoing Support: Our team is available for technical support and suggestions for improvement.

- Continuous Improvement: We invest in new technology and staff training to ensure competitiveness.

With Stratos Moulds And Parts on your side, you can rest assured that your parts will always be at the forefront of performance and quality. Contact us today for more information!

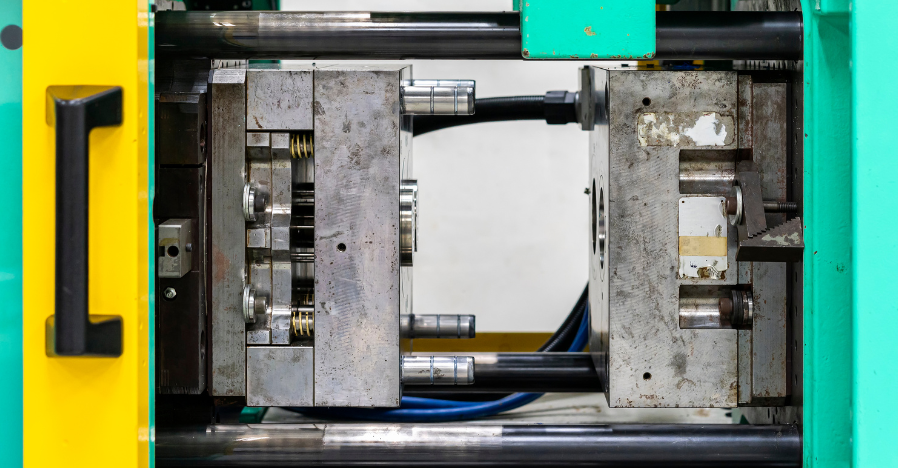

Plastic Manufacturing

Supported by an extensive network of partners with over 40 injection moulding machines, Stratos Moulds And Parts offers flexible and fast λύσεις solutions for plastic component production.

Our manufacturing process is designed to meet the needs of every client, regardless of the size or complexity of the project. Our network of injection moulding machines ranges from 30 to 500 tons, with the capability to produce plastic components weighing up to 1.5 kg.

We invest in technology and expertise to ensure that every product meets the highest standards of quality and performance, delivering solutions that help our clients succeed in the market.

Services

- Wide Range of Materials: We ensure precision and quality finishes on a variety of materials, from metals to composites.

- High Precision Tolerances: Our CNC machines provide millimetre precision, ensuring perfect fit and function of your machines.

- Quality Assurance: Each component is carefully tested to ensure it meets your stringent requirements.

- Custom Designs: We create components according to your exact specifications.

- Durability: Each component is designed to withstand harsh operating conditions. Advantages:

Advantages:

- Flexibility: Ability to manufacture a wide range of components, from prototypes to mass production.

- Rapid Delivery: We leverage an extensive network of suppliers for fast production and delivery.

- Ongoing Support: Our team is available for technical support and suggestions for improvement.

Mould Repairs

The Mould Repair Service of Stratos Moulds And Parts designed to ensure the continued operation and efficiency of your molds. Our technicians have the expertise and tools needed to restore the functionality of your molds, offering solutions that restore your productivity.

Advantages:

- Clear Diagnostics: We perform detailed diagnostics to fully understand your repair needs.

- Cost Effective Solutions: We propose the most cost-effective mold remediation solutions to reduce costs and increase efficiency.

- Strategic Maintenance: We analyze the conditions of each mold and recommend maintenance strategies that ensure long-term functionality.

Lifetime Support and Aftermarket Service

At Stratos Moulds And Parts, we recognise the importance of ongoing support for the success of your business. That's why we offer comprehensive aftermarket services that ensure your products and processes remain in top condition, providing reliable solutions that meet your needs.

Advantages:

Constant Communication: Our team is always available to provide information, technical support and advice on how to make the best use of our products.

Scheduled Maintenances: We offer scheduled maintenance services to prevent problems and ensure the long-term performance of your molds and components.

Rapid Response & Reaction: In the event of any setback occurrence, our team is ready to intervene immediately, offering quick and effective solutions.

Training and Support: We provide training to our customers on the proper use and maintenance of products, ensuring your team can get the most out of the solutions we provide.

Upgrades and Enhancements: Feel free to consult us for potential upgrades or enhancements that can increase the efficiency and functionality of your products.