Stratos Moulds And Parts

The leading name in the mould-making industry since 1977.

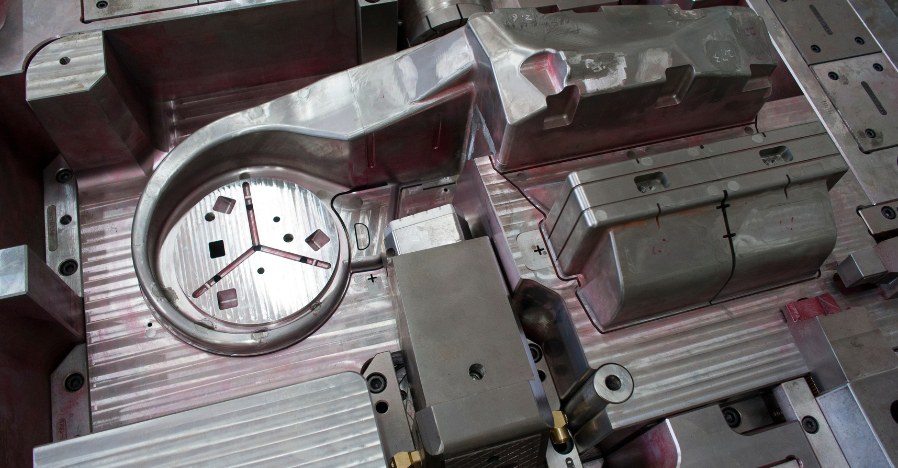

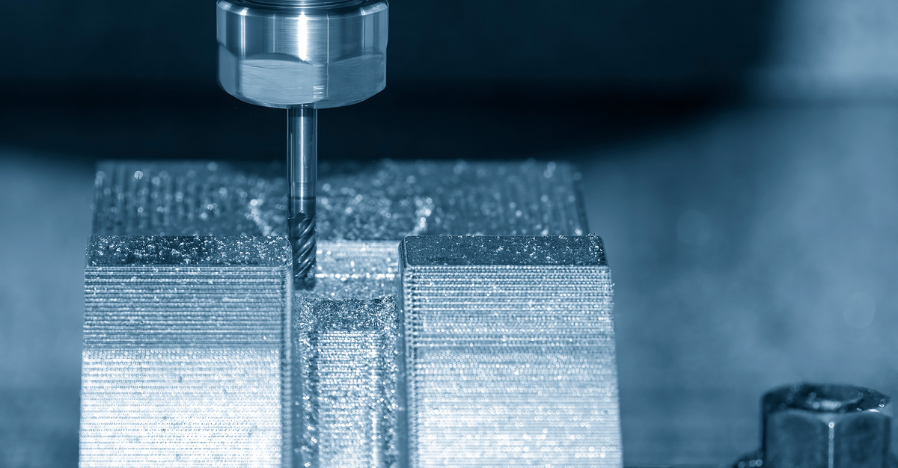

A pioneer in the design and of of high quality high pressure die casting moulds, for injection molding and die casting , specialising in high productivity injection moulds, using heated runners.

With over 45 years of experience, we pride ourselves on our commitment to quality, innovation and customer satisfaction.

45+ years of experience

From initial design to production completion, we offer customized solutions that ensure maximum performance and durability. With moulds up to 700×500 mm (millimetres) and weights up to 600 kg, we specialise in high-productivity moulds using heated runners for optimum performance and excellent production quality.

-

Innovative Design

-

Durability

-

Specialization in High Productivity Moulds with Heated Runners

Our moulds ensure absolute precision in the moulding of each component. We have the capacity to produce moulds with maximum dimensions of 700×500 mm (millimetres) and weights up to 600 kg, offering high quality and reliability.

-

Reliability and Performance

-

Materials Specialisation

-

Extensive Support

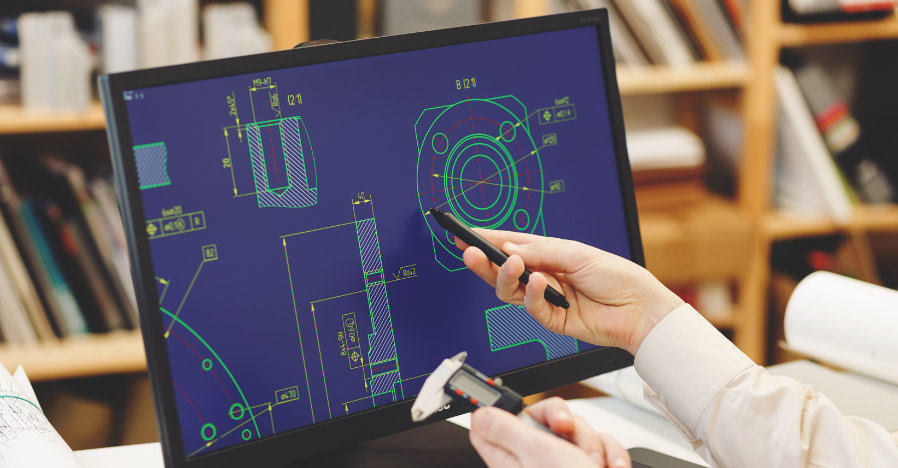

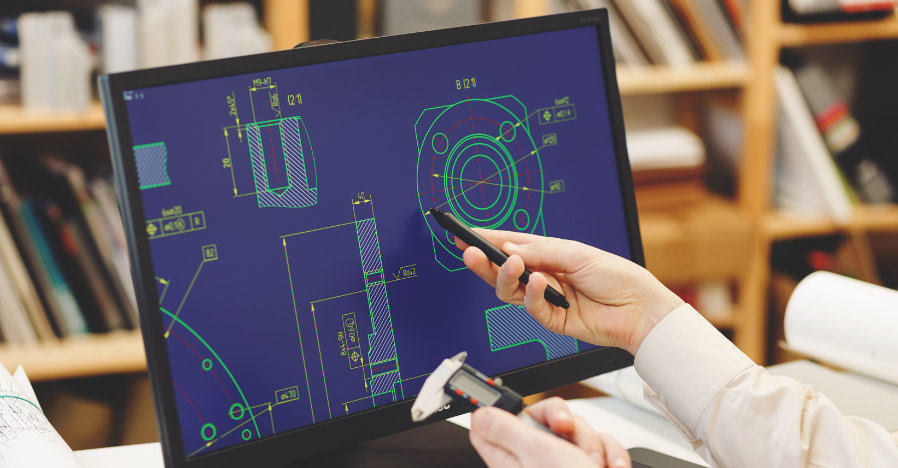

Using state-of-the-art CAD/CAM/CAE tools, Stratos Moulds And Parts offers complete design solutions for the manufacture of high-precision moulds and mechanical components. Our skilled staff uses the latest programs to create optimized designs, which are tested in simulation to achieve maximum product functionality and efficiency.

-

Precise Design

-

Performance Simulation

-

Improved Design

Our company provides not only manufacturing services, but also complete product development solutions that incorporate the latest technology. Our team works closely with clients to develop and improve their products, ensuring they are competitive in the marketplace.

-

Prototyping

-

Existing Products Upgrade

-

Extensive Market Experience

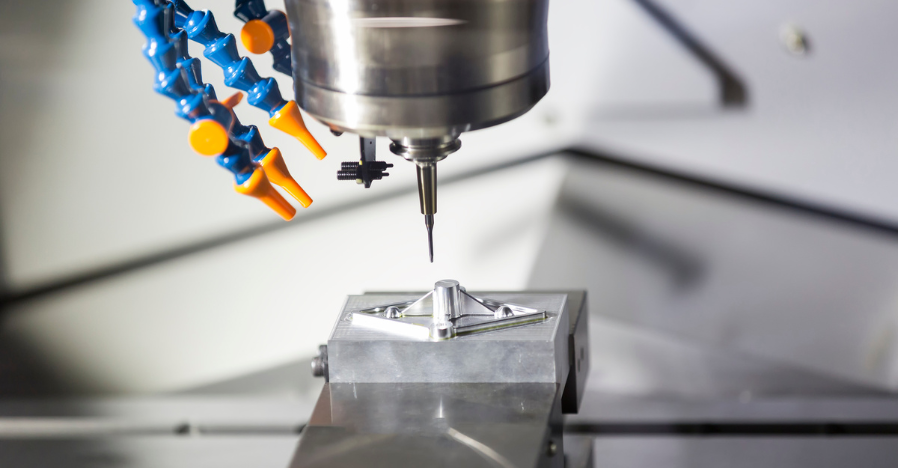

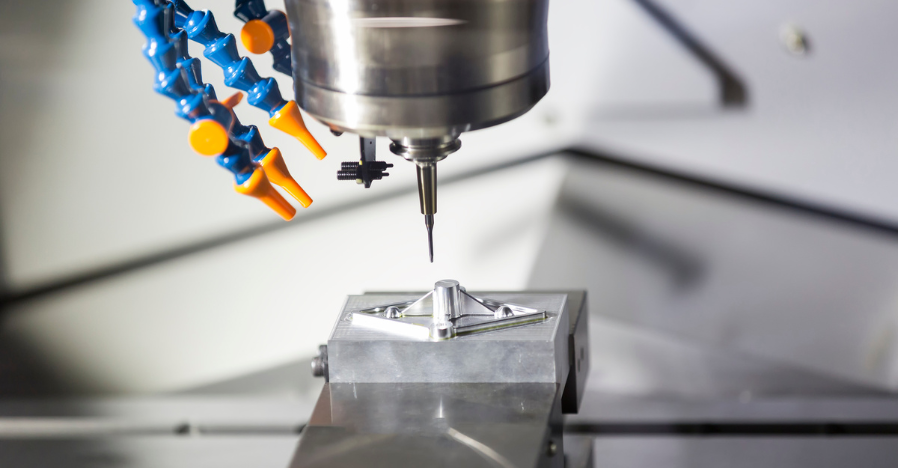

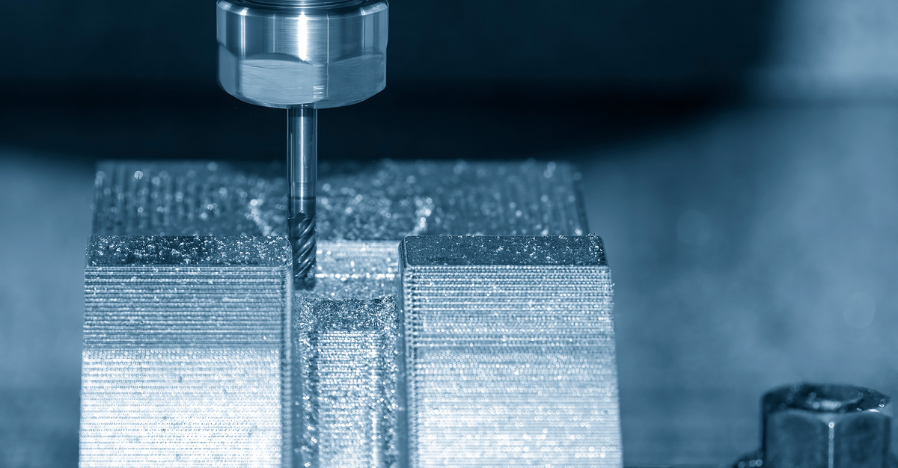

Stratos Moulds And Parts CNC machining ensures the production of precision parts to the highest specifications, using advanced technologies and control systems. Our expertise in precision CNC part manufacturing, combined with our specialized processes, ensures that every part is produced with millimeter precision and absolute attention to detail, meeting even the most demanding applications.

-

Precise Design

-

Rapid Delivery

-

Ongoing Support

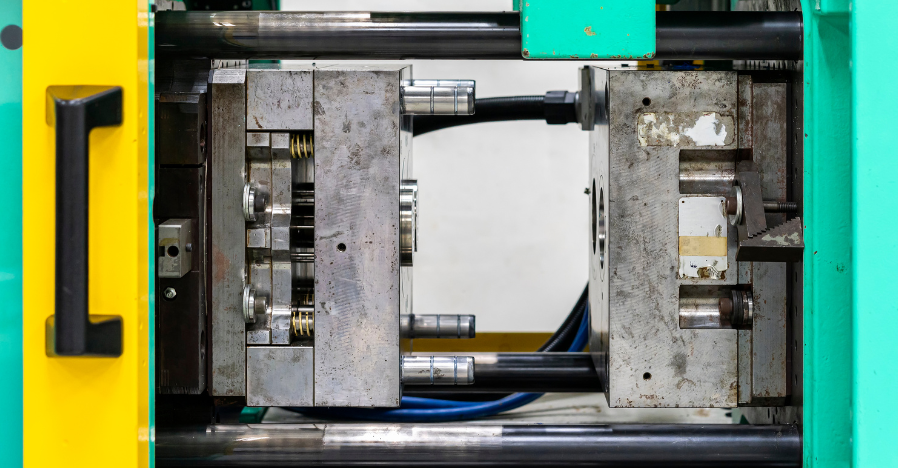

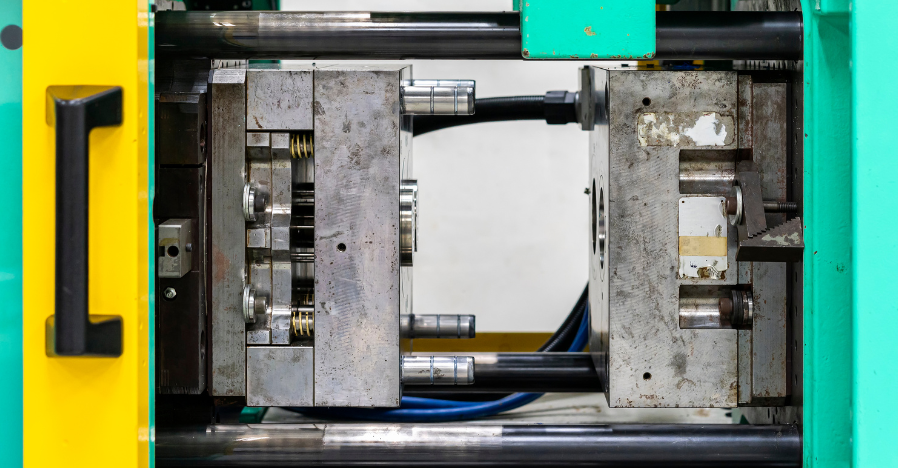

Our production process is designed to meet the needs of every customer, regardless of size or complexity. We are supported by an extensive network of partners with over 40 injection moulding machines, ranging from 30 to 500 tons. The maximum weight of the plastic produced is up to 1.5 kg, ensuring flexibility and efficiency in production.

-

Fast Delivery Times

-

Variety of Materials

-

Excellent Customer Support

Our technicians have the expertise and tools needed to restore the functionality of your molds, offering solutions that restore your productivity.

-

Clear Diagnostics

-

Cost Effective Solutions

-

Strategic Maintenance

We offer comprehensive aftermarket services that ensure your products and processes remain in top condition, providing reliable solutions that meet your needs.

-

Constant Communication

-

Scheduled Maintenances

-

Rapid Response & Reaction

From initial design to production completion, we offer customized solutions that ensure maximum performance and durability. With moulds up to 700×500 mm (millimetres) and weights up to 600 kg, we specialise in high-productivity moulds using heated runners for optimum performance and excellent production quality.

-

Constant Communication

-

Scheduled Maintenances

-

Rapid Response & Reaction

Our moulds ensure absolute precision in the moulding of each component. We have the capacity to produce moulds with maximum dimensions of 700×500 mm (millimetres) and weights up to 600 kg, offering high quality and reliability.

-

Constant Communication

-

Scheduled Maintenances

-

Rapid Response & Reaction

Using state-of-the-art CAD/CAM/CAE tools, Stratos Moulds And Parts offers complete design solutions for the manufacture of high-precision moulds and mechanical components. Our skilled staff uses the latest programs to create optimized designs, which are tested in simulation to achieve maximum product functionality and efficiency.

-

Constant Communication

-

Scheduled Maintenances

-

Rapid Response & Reaction

Our company provides not only manufacturing services, but also complete product development solutions that incorporate the latest technology. Our team works closely with clients to develop and improve their products, ensuring they are competitive in the marketplace.

-

Constant Communication

-

Scheduled Maintenances

-

Rapid Response & Reaction

Stratos Moulds And Parts CNC machining ensures the production of precision parts to the highest specifications, using advanced technologies and control systems. Our expertise in precision CNC part manufacturing, combined with our specialized processes, ensures that every part is produced with millimeter precision and absolute attention to detail, meeting even the most demanding applications.

-

Constant Communication

-

Scheduled Maintenances

-

Rapid Response & Reaction

Our production process is designed to meet the needs of every customer, regardless of size or complexity. We are supported by an extensive network of partners with over 40 injection moulding machines, ranging from 30 to 500 tons. The maximum weight of the plastic produced is up to 1.5 kg, ensuring flexibility and efficiency in production.

-

Constant Communication

-

Scheduled Maintenances

-

Rapid Response & Reaction

Our technicians have the expertise and tools needed to restore the functionality of your molds, offering solutions that restore your productivity.

-

Constant Communication

-

Scheduled Maintenances

-

Rapid Response & Reaction

We offer comprehensive aftermarket services that ensure your products and processes remain in top condition, providing reliable solutions that meet your needs.

-

Constant Communication

-

Scheduled Maintenances

-

Rapid Response & Reaction